In today’s construction industry, achieving flawless plastering finishes is essential for both aesthetics and building protection. Mastering professional plastering techniques is particularly crucial when working with external wall insulation systems – an area where precision and expertise make all the difference between mediocre results and exceptional quality that stands the test of time.

Why Professional Plastering Matters for External Wall Insulation

When installing external wall insulation, the plastering stage represents the final protective barrier for your building envelope. A properly executed plastering job not only creates a visually appealing finish but also ensures the entire external thermal system performs optimally for decades.

Studies show that up to 40% of external wall insulation system failures can be attributed to poor plastering workmanship. This makes mastering professional plastering techniques an essential skill for contractors working with these systems.

The Critical Role of Plastering in Building Protection

High-quality plastering on external wall insulation systems provides:

- Effective weatherproofing against Britain’s challenging climate

- Prevention of moisture ingress that could compromise insulation performance

- Protection against physical damage to the underlying insulation materials

- The foundation for decorative finishes that enhance property value

Essential Plastering Tools for External Wall Insulation Projects

Investing in professional-grade tools is non-negotiable for quality plastering work on external wall insulation. The right equipment ensures precision, efficiency, and consistency across your projects.

Must-Have Plastering Tools for External Applications

Every professional plasterer working with external wall insulation systems needs a comprehensive toolkit including:

- Plastering Trowels and Floats

- Mixing Equipment

- Application and Finishing Tools

Find professional-quality plastering tools here that meet the demanding requirements of external wall insulation applications.

Premium Materials for External Wall Insulation Plastering

The quality of plastering materials significantly impacts both the application process and long-term performance of external wall insulation systems. Using premium-grade materials is particularly important in the UK’s variable climate.

Base Coats and Adhesives

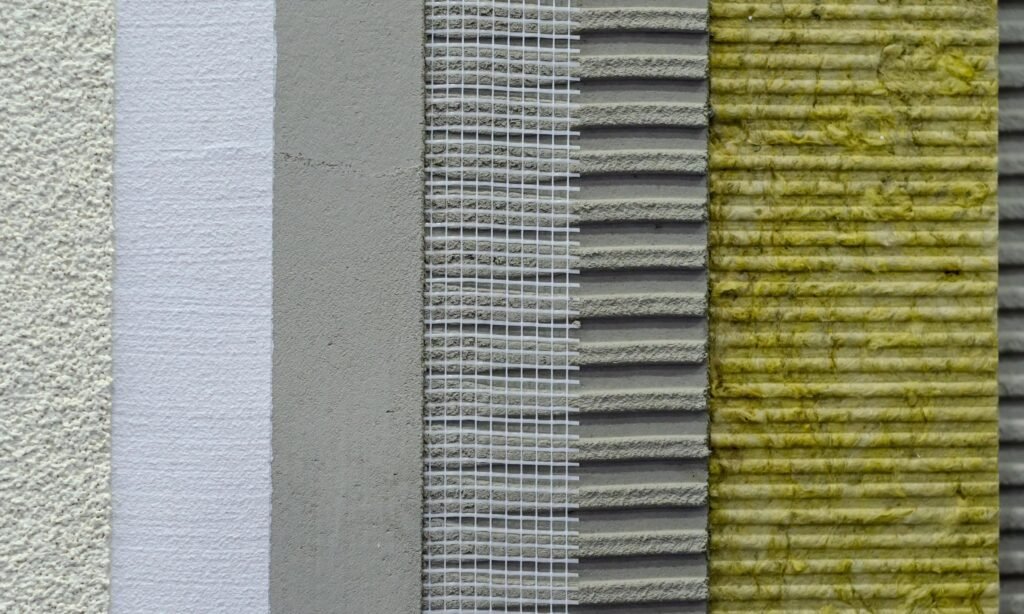

The foundation of any successful external wall insulation system begins with high-performance base coats and adhesives. These materials create the critical bond between the insulation boards and the substrate.

Premium adhesives and foam adhesives should offer:

- Excellent adhesion properties

- Flexibility to accommodate building movement

- Resistance to freeze-thaw cycles

- Compatibility with various insulation materials

Reinforcement Materials

Reinforcement mesh is essential for preventing cracks and ensuring the longevity of external wall insulation systems. Quality polystyrene fiberglass mesh and fixing materials provide:

- Structural strength to the plastering layers

- Resistance to alkaline environments

- Optimal embedment capabilities

- Dimensional stability under varying conditions

Premium Fibreglass Mesh Reinforcement

Our bestselling reinforcement mesh provides excellent strength and durability for all external wall insulation systems. Designed to prevent cracking and ensure long-lasting results.

- High tensile strength

- Alkali resistant

- Easy application

- Professional grade quality

£45.83 ex. VAT

View ProductPrimers and Undercoats

Professional primers and undercoats are crucial for:

- Ensuring proper adhesion between layers

- Regulating substrate absorption

- Preventing discoloration of finish coats

- Enhancing overall system durability

Finish Renders

The final aesthetic and protective layer of external wall insulation systems comes from quality renders. Professional-grade renders should provide:

- Excellent water repellency

- Vapour permeability for building breathability

- UV resistance to prevent color fading

- Crack resistance for long-term performance

Silicone Render Tynksil QS 25kg

Premium silicone render providing exceptional water repellency and durability for external wall insulation systems. Available in a wide range of colors to achieve the perfect finish for any project.

- Superior water resistance

- Highly breathable

- UV and weather resistant

- Self-cleaning properties

£58.33 – £59.16 ex. VAT

View ProductStep-by-Step Plastering Techniques for External Wall Insulation

1. Surface Preparation: The Foundation of Excellence

Proper preparation determines 50% of your plastering success. For external wall insulation systems, this means:

- Ensuring insulation boards are firmly attached and properly aligned

- Creating level surfaces by sanding any proud areas of insulation

- Applying appropriate corner and edge reinforcements

- Checking and addressing any potential weak points in the system

2. Base Coat Application Techniques

The base coat application is critical for the overall strength and durability of the external wall insulation system:

- Apply the base coat using a notched trowel at a consistent thickness (typically 6-8mm)

- Embed the reinforcement mesh immediately while the base coat is still wet

- Ensure mesh is completely covered with no visible pattern showing through

- Allow proper curing time according to manufacturer specifications

3. Primer Application: Creating the Perfect Foundation

A quality primer creates the ideal surface for the final render:

- Apply primers using a roller or spray equipment for even coverage

- Ensure complete coverage with no missed spots

- Allow full drying time as per technical specifications

- Verify surface is ready for final render application

4. Finishing Techniques for Different Render Types

Various render finishes require specific application techniques:

- Scraped Finishes: Apply 15mm thickness and scrape when thumbprint hard

- Floated Finishes: Apply at 10-15mm and float with appropriate tool when setting

- Roughcast Finishes: Apply base and then throw on aggregate mix for texture

- Silicone Renders: Apply thinly and texture immediately before setting begins

Avoiding Common Plastering Mistakes in External Wall Insulation

Even experienced plasterers can encounter issues when working with external wall insulation systems. Here are key pitfalls to avoid:

1. Incorrect Mixing Ratios

Following manufacturer specifications for mixing ratios is non-negotiable. Too much water weakens the render, while too little creates application difficulties and poor adhesion.

2. Working in Unsuitable Weather Conditions

External plastering requires appropriate weather conditions:

- Avoid application in temperatures below 5°C or above 30°C

- Never apply renders in direct sunlight on hot days

- Protect freshly applied materials from rain and frost

- Consider wind conditions which can accelerate drying times

3. Insufficient Reinforcement at Stress Points

Building stress points require additional reinforcement:

- Window and door corners need diagonal mesh reinforcement

- Expansion joints must be properly incorporated

- Material transitions require special detailing

4. Rushing the Process

Each stage of plastering requires proper curing time. Rushing between layers compromises the entire system’s performance.

Advanced Finishing Details for External Wall Insulation

The difference between average and exceptional external wall insulation systems often lies in the details:

Professional Edge Finishing

Creating clean, straight edges with facade profiles elevates the overall appearance of external wall insulation systems and provides:

- Clean architectural lines

- Additional weather protection at vulnerable points

- Professional aesthetics that enhance property value

Texture and Pattern Variations

Modern renders allow for a wide range of decorative possibilities:

- Traditional sand-cement textures

- Contemporary smooth finishes

- Patterned and textured effects

- Regional and period-appropriate styles

Maintaining External Wall Insulation Plastering

Proper maintenance ensures the longevity of external wall insulation systems:

- Inspect regularly for cracks or damage

- Clean surfaces annually with appropriate methods

- Address minor issues before they become major problems

- Follow manufacturer maintenance recommendations

Recommended Products for External Wall Insulation

Based on our professional experience and customer feedback, we recommend these top-performing products for your external wall insulation projects:

Conclusion: The Path to Plastering Excellence for External Wall Insulation

Mastering professional plastering techniques for external wall insulation systems requires knowledge, practice, and access to quality materials. By investing in professional tools, using premium materials, and following best-practice application techniques, contractors can deliver exceptional results that protect buildings and enhance their appearance for decades.

For comprehensive external wall insulation solutions, including professional-grade plastering materials, tools, and accessories, explore our complete range of external wall insulation products.

Related Articles Explore more of our expert guides to external wall insulation:

- External Wall Insulation Cost in the UK

- Before and After External Wall Insulation

- External Wall Insulation Fixings: Complete Guide

- How to Select the Right Adhesive for Different External Wall Insulation Materials

- Choosing the Right Render for External Wall Insulation: A Complete Guide

- External Wall Insulation: Professional Plastering Guide

Visit our Blog for more valuable insights and expert advice on external wall insulation and other building materials.

This article was prepared by industry experts with extensive experience in external wall insulation systems and materials. The information provided is based on current best practices and manufacturer recommendations as of May 2025.